January 3, 2024 - Ross Video Team, Education

3 Ways Modular Design Reduces Environmental Impact

The video production industry faces a pressing challenge: aligning technological advancements and growing audience demands with sustainability.

How can our industry evolve and improve without expanding its environmental footprint?

In a recent SMPTE Journal article, we argued the answer may be modular technology. Here’s why this innovative approach to the design of video production infrastructure is poised to reshape the industry.

Modular design refers to creating systems with interchangeable parts or modules. This approach revolutionizes traditional production setups, where purpose-built, monolithic equipment is the norm.

Unlike conventional designs that rely on a multitude of discrete hardware, modular design integrates multiple functions into a single, compact unit with interchangeable components. It’s especially relevant in video production and broadcasting due to the industry’s dynamic nature, where adaptability and space efficiency are crucial.

Computers exemplify modular design (or at least, used to), featuring easily interchangeable components like chassis, power supply units, processors, and graphics cards. This modularity facilitates user-driven upgrades and repairs, bypassing the need for complete system replacement.

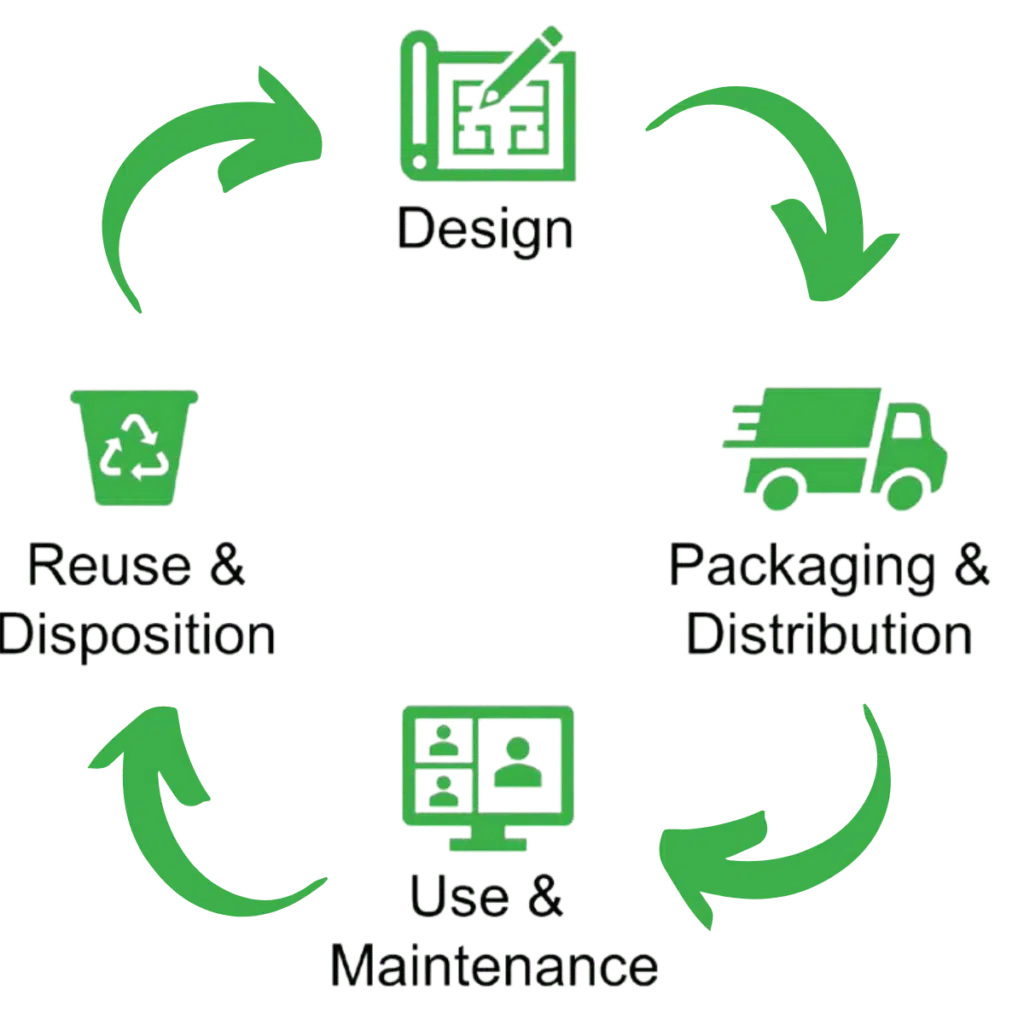

One of the most significant benefits of modular design is its contribution to waste reduction. By extending equipment life and minimizing the need for frequent replacements and system overhauls, modular solutions significantly cut down on e-waste.

For instance, in data center operations, modular designs have allowed for more efficient cooling and power systems, significantly reducing energy consumption. The U.S. Department of Energy has noted that modular data centers could achieve up to 50% energy savings compared to traditional data centers.

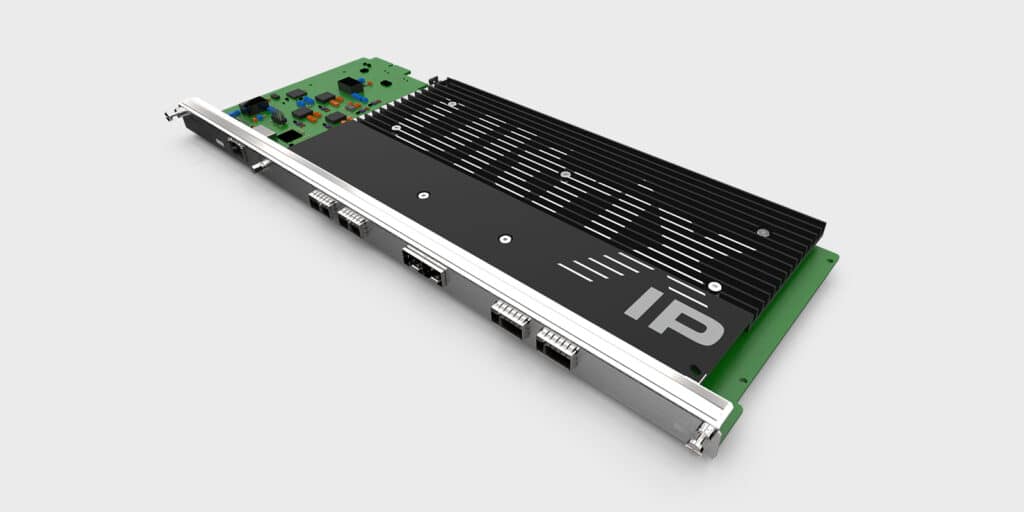

This approach is still new to video production equipment, with innovations like Ultrix being among the first to offer modular components that can be individually upgraded. That allows customers to adopt new technologies that support new standards with lower environmental impacts — and costs!

Modular equipment production and deployment requires fewer resources than traditional systems.

The smaller size and weight of modular components leads to a lower carbon footprint, both in manufacturing and in deployment over its lifetime — an important consideration for mobile productions and outside broadcasters that are frequently on the move.

That can significantly decrease energy consumed for transportation of equipment, cabling, and operators associated with traditional production systems — for the entire product lifetime.

Adopting modular designs presents opportunities for cost savings alongside environmental benefits and will save money in the long run — in most cases.

Modular design reduces operational costs in several ways, including:

Modular design standardizes parts, simplifying production. That allows for automated assembly line systems, which reduce complexity and increase output.

Modules can be produced independently and simultaneously, decreasing production time. Isolating issues in a single module prevents impacts on the entire product, further accelerating production and repair.

Using standardized modules across different products reduces the need for unique components, lowering production costs.

Modular design enables the creation of various product configurations to meet diverse customer needs, enhancing market responsiveness.

Independent design and testing of each module enhance product reliability and performance. Standardization ensures product consistency, reducing defects and improving reliability.

The long-term implications of the shift to modular technology could be profound. Modular technology aligns the video production industry with global efforts to combat environmental degradation by reducing waste, lowering energy consumption, and enhancing equipment longevity. Ultrix represents more than just innovation; it’s our commitment and investment in a more sustainable and efficient video production industry.

To learn more about how hyperconverged design reduces the environmental impact of production technologies, read the full SMPTE article here (academic subscription required).

The award-winning Ultrix 12G Router is the ultimate routing, multiviewer, and signal processing platform for Studios, OB Vans, and Flypacks. Learn more about the only modular, software-defined video production infrastructure available today on the Ultrix product page.

Ross Video’s 2D and 3D real-time motion graphics system received a significant boost with major updates to the XPression engines, along with the version 12 software that …

Sports broadcasters and live event venues demand tools that are reliable, adaptive, and packed with dynamic features to help draw fans deeper into the action. PIERO is …

Remote production is shifting rapidly, driven by new technologies and evolving workflows. In a recent webinar hosted by TV Tech, Ross Video’s VP of Production Services, Stephen …

We’ll put you in touch with a member of our team to discuss your specific needs.