Company

A Brief History Of Our Switchers

1974

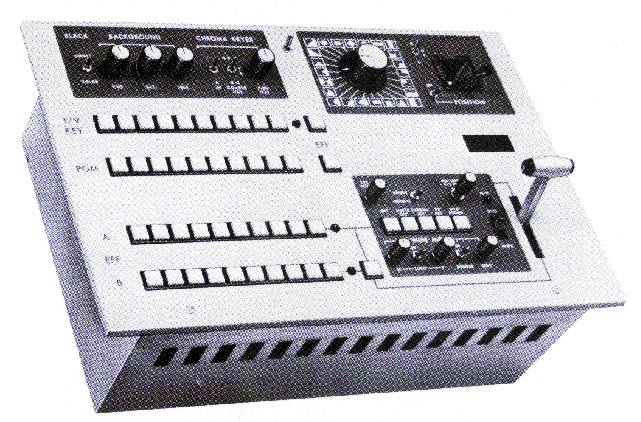

10-4 & 16-4

John Ross founded Ross Video in Canada in 1974. He sold an airplane he had just refurbished for just 00 and also used his personal savings of 0 to start the company. The first switcher, the 16-4, was entirely designed and built in the basement of his house.

The 16-4 was a marvel of compact analog engineering of its time. It may not sound impressive now, but to fit all of the electronics of a high quality 1 MLE switcher into a 2 RU chassis was unheard of in 1974. This was made possible by John Ross’ deep understanding of video and analog design. As an interesting side note, 15 years later, this first switcher, serial number 1, was given back to Ross Video in perfect condition and working order.

The 16-4 became a series of switchers which were so successful that the company began to grow rapidly. The 16-6 model was used exclusively by the CBC (International Broadcasting Centre) during the 1976 Montreal Olympics.

1978

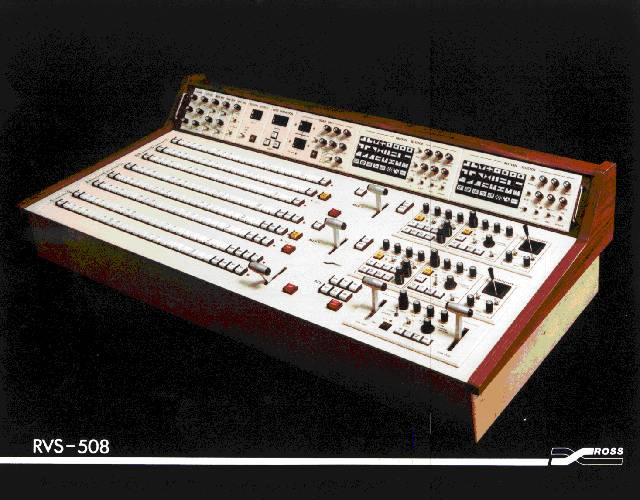

500 Series

The next series of switchers, launched in 1978 only three years later, was a major jump forward introducing the now industry standard “Next Transition Operation” concepts including the first patent for “Transition Preview” now copied by almost all higher end switchers made in the industry.

A great example of the second generation of switchers is the RVS-508, a 2.5 MLE switcher that sold successfully all around the world. As before, the 508 eventually became a line of many different sizes of switchers known as “the 500 series”. The RVS-508 and RVS-505 were used extensively by the Australian Broadcasting Corporation during the 1982 Commonwealth Games held in Brisbane.

Analog switchers, such as the 508, were very challenging to manufacture compared to today’s digital switchers. Depending on the size of the switchers and the options purchased, a large analog switcher could spend 4 to 8 weeks in the test department being calibrated before it was ready for a customer to use! Today, of course, a 4 MLE digital switcher can be tested in less than a day!

The 500 series switchers predated the use of microprocessors and high speed serial communication between the control panel and rack frame electronics. Dozens of cable bundles were used to connect between the panel and the rack frame. The cable bundles contained many wires to individually connect the buttons, faders, and knobs in the panel to corresponding sections of analog circuitry in the chassis. As the distances between the control panel and the chassis were different for every customer, the calibration of the circuits in the frame would have to be custom adjusted for the length of the wires going back to the control panel. There is a sad but amusing story of one customer that wanted a quick “touch up” to his switcher and sent it back to the factory with all of the cables cut. The “touch up” turned into weeks of recalibration work.

Later in the life of the 500 Series, when customers wanted memories for their switcher, this was no simple task to add. There was a very expensive switcher option for the 500 series called “Encore” that added a large chassis to the system. The control panel was connected to this chassis and all of the knob and button sections were converted to digital. This was then stored in a microprocessor for later recall. The processor then took the desired values and converted them back to analog and sent them to the main switcher chassis, as if the chassis was talking to a control panel. Clearly, there was an opportunity here for a revolution in production switcher technology!

1985

RVS Series

The next series of switchers incorporated the microprocessors directly into the control panel and reduced those huge cable bundles into a single serial data connection to a new generation of chassis electronics. The microprocessor in the chassis would then convert the desired values sent from the panel into analog values that controlled the analog circuits. Test time and cost was dramatically reduced and now the control panels could be any distance from the chassis, easily changed by the customer.

This series of switchers included products ranging from the 1 MLE RVS-210A up to the RVS-630 a 2.5 MLE switcher. The RVS-210A proved so popular and stable, it sold for 25 years – a long time for any technology product.

1995

CDK-104

1995 saw Ross create a new class of small switcher specifically targeted at Telecine operations. The CDK-104 had features like side by side and diagonal compare, test chroma key, and specialized letterboxing masks. It was intended to be used downstream of color corrector systems. The CDK became known as “The Telecine Switcher” and created a new product category. The CDK-104 became a fixture in most telecine suites around the world.

1998

Synergy Series

The following jump was a very big one for Ross Video going from composite analog switchers to component digital switchers. This was the introduction of the award winning Synergy Series in 1998. Synergy was the first production switcher line that David Ross, John’s son with a degree in computer engineering had total responsibility for. The Synergy Series was ground breaking in many ways. Synergy doubled the maximum inputs up to 64, and expanded the range of sizes from 1 MLE to 4 MLE. Synergy, eventually known as “Synergy SD”, became a world-wide success selling well in excess of 3000 units. When introduced, the 11 RU Synergy frame was by far the most compact in the industry and used only about one tenth the power of its competition.

Synergy was also the first large switcher to incorporate a built-in DVE, and came with up to 8 channels of Squeeze & Tease 2D DVE which a few years after introduction evolved to 8 channels of extremely powerful 3D DVE known as “Squeeze and Tease WARP”.

2004

Synergy MD/X Series & OverDrive

In 2004, Ross introduced Synergy MD/X, marking Ross’s entry into High Definition production switching. The Synergy MD/X system offered a new Multi-Definition rack frame processing electronics, paired with the current Synergy control panel, which had evolved significantly from introduction. This approach provided an upgrade path for Synergy SD customers allowing them to connect their existing control panels to a new and more powerful multi-definition chassis. This new chassis was another huge technological leap forward in high definition production switchers, condensing 4 MLEs, 16 channels of MD DVE, 96 inputs, 48 outputs, and 19 channels of full screen animation playout into just 8 RU. The MD/X chassis also introduced the concept of mixing and keying on Aux Buses, trademarked as AuxKeys – something never done before, again with patents pending. MD/X was years ahead of it’s time in terms of price and performance.

2004 also saw Ross Video debut the OverDrive Automated Production Control System. This system pioneered live Newsroom MOS integration from Newsroom editorial systems, directly connecting the Newsroom rundown into OverDrive. OverDrive takes the rundown and translates it into on air operations, allowing a single operator to control all aspects of a live production via a simple, easy to use touch screen, keyboard and mouse.

OverDrive provided a tight integration with Synergy SD & MD/X as well as controlling robotic cameras, character generators, audio mixers, audio servers, video servers, and other devices used in live production. OverDrive quickly became the leader in live automated production, outselling the competition and enabling a quality of on air production not thought possible under automation control.

2007

Vision Series

Launched in 2007, the Vision control panel series released even more capability from the MD/X chassis with a more powerful modular control surface and touch screen, dual menu system. Vision was the first switcher to use RGB buttons in full 30-bit color with a stunningly beautiful and functional result. For the first time, it became possible for users to fully color code the M/E rows as well as color grouping related sources – another patent pending innovation.

2008

QMD/X Series & CrossOver

In 2008, Ross launched the QMD/X series, two new processing chassis, the 3RU QMD and the 8 RU QMD/X chassis. The QMD chassis packs an incredible 4 MLEs, 8 channels of 3D DVE, 19 channels of animation store, and 48 inputs into just 3 RU. And when we say 3 RU we mean it – no extra boxes on top to complete a system!

At the same time that QMD/X was launched, Ross also introduced the compact CrossOver 1 M/E series of production switchers, which use same video processing technology. CrossOver sets the compact production switcher bar high, with high end features and functions not seen at this size and price point.

2009

Vision Octane

At IBC 2009, Ross launched Vision Octane, the world’s first 8 MLE production system with up to 24 channels of 3D DVE with Warp and more. Another leapfrog ahead in production power, Vision Octane gives high intensity production environments like multi-screen, multi-panel and split feed situations the production power required to deliver results.

2010

Internal MultiViewers

At IBC 2010, internal MultiViewers were added to the Vision series, another industry first for large production switchers. To add to the innovation, the MultiViewers were designed to use existing MLE hardware in the system, just reprogrammed for the new application. This means that an Octane system can have any combination of MultiViewer heads and MLEs that adds up to eight.

2011

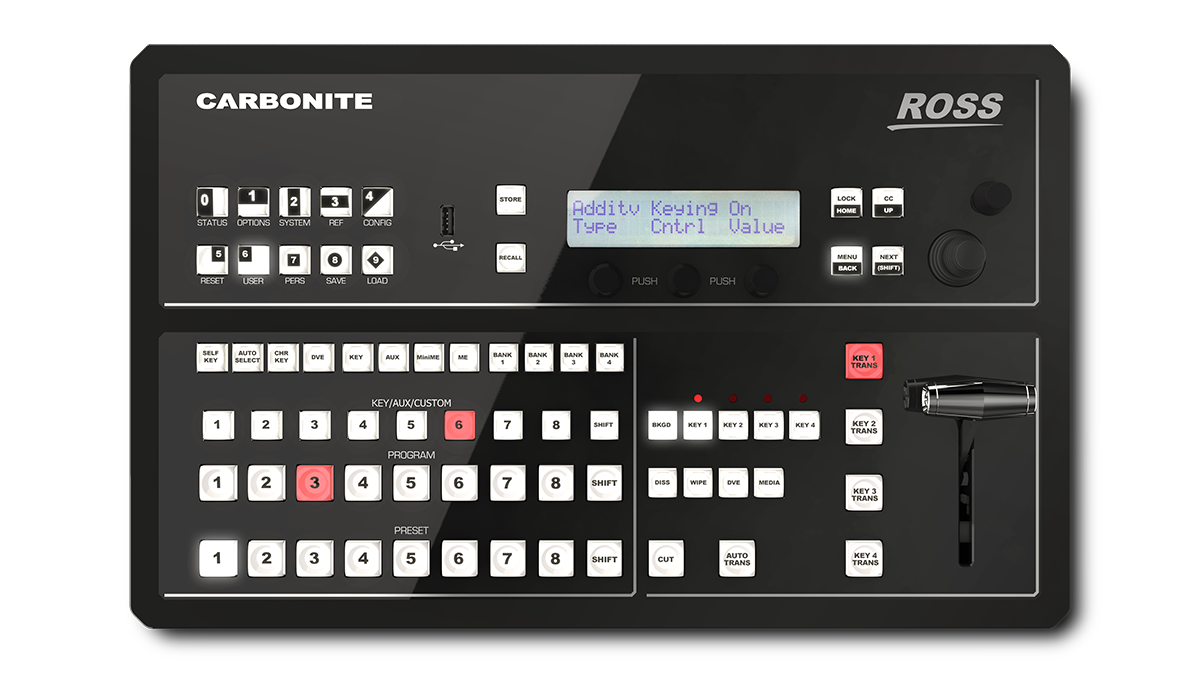

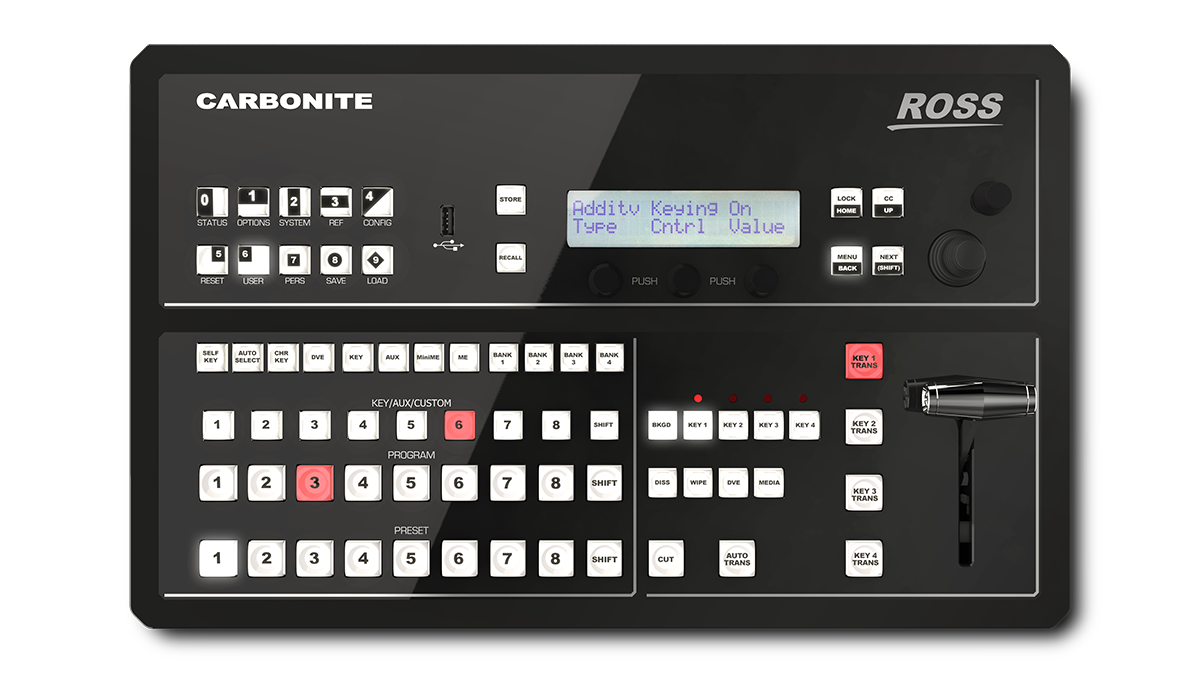

Carbonite Series

NAB 2011 saw the introduction of a blockbuster new switcher line: Carbonite. Carbonite set a radically new price/performance level for higher end 1 and 2 MLE switchers. The rack is just 2 RU but is packed with 24 HD-SDI inputs, dual MultiViewers, up/down converters, DVEs, impressive Media Stores, and the world’s first web-based multi-user GUI. More purchase agreements were signed for Carbonite on the show floor than any previous switcher in Ross Video’s long history.

2012

Extended Carbonite Series

In 2012 the Carbonite feature set was dramatically increased and several new control panels were added.

2013

Carbonite Extreme

2013 saw the introduction of Carbonite Extreme – a unique combination of routing system and production switcher. New and very powerful features were added for all Carbonites. These included MiniME and MultiScreen modes that effectively doubled the production power.

In 2013 we introduced Vision Tritium, a powerful yet cost efficient version of the Vision Octane series. This large 3ME switcher provided a very affordable production tool to customers with limited budgets.

2014

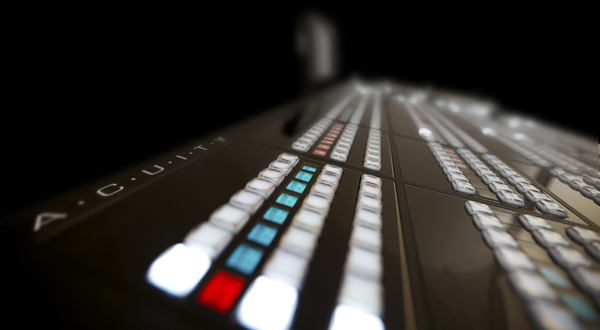

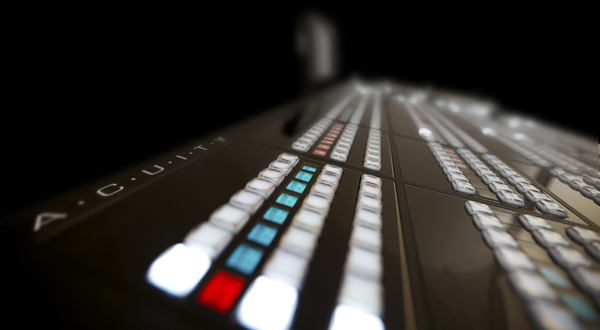

Acuity Series

The Acuity production switcher was introduced at NAB 2014 as the next generation replacement for the Vision series. At introduction Acuity, was amoungst the most powerful and competant large production switchers in the world, capable of managing all current video formats without feature reduction. It was instantly met with success and was quickly embraced for several high profile events. Acuity evolved rapidly over the next few months to include UHD (4K) capabilities, multiple ME outputs that are completely configurable, together with a massive increase in keying and DVE capabilites. It remains the most powerful switcher available today.

2016

Carbonite Black Solo Series & Extended Carbonite Black Series

In 2016, Ross Video introduced another compact switcher powerhouse – Carbonite Black Solo. All the features that made the Carbonite series an industry gold standard were packed into this single ME switcher. Carbonite Black Solo was meant to fit perfectly in smaller productions where quality and operational performance are essential, in a package that is remarkably affordable.

Ross Video also expanded the Carbonite Black line with the Carbonite Black Plus. This switcher is a signal processing marvel with frame synchronizers, format converters, color correction and proc amps on every one of its 36 inputs. Carbonite Black Plus provided the necessary features to match on set displays and output multiple formats.

2017

Graphite, Carbonite UHD and Acuity UHD

Yet another landmark year for cost-effective and compact production, 2017 saw the introduction of the 4RU Graphite All-In-One Production system which merged the power of a full 2ME Carbonite production switcher with a single channel of powerful XPression graphics, two channel XPression Clip Server, and twenty-eight channel RAVE audio mixer. Uniquely, Graphite was built with dedicated hardware that addressed the common performance issues and failures that traditional all-in-one users consistently faced.

2017 also showcased the incredible growth that results from Ross Video’s platform-based approach to product development. The features that were unlocked through software version downloads – at no additional cost to customers – were staggering. Carbonite Black and Black Plus received full UHD switcher functionality, the Carbonite Black Solo had a built-in USB media player activated, and the Acuity series vastly simplified UHD production and added VirtualPanel functionality.

Looking back roughly four decades of production switcher history, Ross has continued to generate compelling innovations that have moved production switcher technology forward. Our passion for live production technology continues – and many new and exciting innovations lie ahead.

Ross is still a family-owned company to this day. While many companies have come and gone, Ross has steadily grown through innovation and taking care of our customers. We feel that even though we’ve grown greatly, it’s an equal accomplishment to hear from customers that we are still great to work with after all of these years.

2019

Carbonite Ultra

Released in early 2019, Carbonite Ultra distills the best elements of the Carbonite series into a single, next-generation platform. This incredibly versatile piece of hardware redefines midsize production switcher performance – it’s more powerful, more compact, and more affordable than ever before.

Within a brand new 1RU chassis, Carbonite Ultra offers 24 inputs, 14 outputs, and an improved version of the flexible Carbonite feature set. It’s configurable with 1-3 MEs, a complete I/O signal-processing toolkit, and comprehensive MultiViewer monitoring resources. It also supports all common video standards, including SD, HD, 3G 1080P, and 12G UHD for multi-ME configurations.

2020

Graphite Portable Production Center

The introduction of the Graphite Portable Production Center (PPC) marked another step in delivering cost-effective and compact production options for our customers. Graphite PPC packages all the professional-quality features of Graphite into a single compact carrying case.

The system uses the same DashBoard virtual control interfaces to allow a single operator to manage an entire show. What’s more, Graphite PPC’s ultra-quiet fans enable the system to be deployed just about anywhere, even in-studio next to the on-air talent.

2020

TouchDrive

The TouchDrive series of control panels debuted in 2020, introducing touchscreen technology to video production switchers.

Designed to reinvigorate the relationship between the Technical Director and their control panel, every display on the TouchDrive is touch-enabled, putting important features and commands at the operator’s fingertips.

2021

Ultrix Acuity and Ultrix Carbonite

Eight years after the groundbreaking Carbonite Xtreme of 2013, the launch of Ultrix Acuity and Ultrix Carbonite marked another transformative milestone in Ross Video’s production switcher history.

Carbonite Xtreme housed a production switcher in a router chassis. Ultrix Acuity and Ultrix Carbonite exploded the functionality of the humble production switcher, using a revolutionary Software-Defined Production Engine (SDPE) card to combine Ultrix’s routing and audio processing capabilities with the functionality of the Acuity and Carbonite Production Switchers.

These new hyperconverged production platforms take routing, audio mixing, MultiViewers, trays of frame syncs, and audio embedders – all solutions that have traditionally filled multiple equipment racks – and compress them into a single chassis.

2022

Graphite Cloud Production Center (CPC)

As the live production landscape continued to evolve, we introduced the cloud-enabled Graphite Cloud Production Center (CPC). Graphite CPC provides the same powerful production switcher, 3D graphics and clip engine, and audio mixer as its hardware-based cousin but eliminates the need for on-prem hardware.

2023

Carbonite Ultra 60

As the biggest, fastest, and most powerful Carbonite production switcher to date, Carbonite Ultra 60 was unveiled in 2023, offering the performance of a large switcher in a compact, cost-effective hardware platform. With modular I/O boards that provide up to 60 Inputs and 25 Outputs, and up to three full MEs in HD or UHD, this new class of production switcher is designed to meet your production needs now and in the future.